Gorilla Glass, a chemically strengthened glass developed by Corning, is a significant innovation in modern technology, especially in the realm of touchscreen devices like smartphones, tablets, and laptops. According to the article, it is an alkali-aluminosilicate sheet glass known for its resistance to damage, designed to withstand scratches and impacts better than regular glass. The importance of Gorilla Glass in today’s technology landscape cannot be overstated; it protects billions of devices worldwide, providing durability, clarity, and touch sensitivity essential for the functionality and longevity of touchscreens. Originally developed in the 1960s for automotive and aerospace applications, Gorilla Glass found its true potential with the rise of touchscreen electronics, largely due to a challenge from Apple’s Steve Jobs in 2006. This led to widespread adoption of Gorilla Glass in the consumer electronics market. Its unique properties, such as high fracture toughness and flexibility, have also made it suitable for use in microelectromechanical systems (MEMS), showcasing its versatility. Advances in the material’s composition, including the integration of hard aluminum-magnesium boride films, have further improved its critical load resistance, demonstrating ongoing innovations in its development. Additionally, Gorilla Glass’s ability to be used in anodic bonding in MEMS/NEMS applications, despite its high thermal expansion coefficient, highlights its importance in the evolution of modern technology. Therefore, Gorilla Glass represents a significant advancement in material science and continues to be crucial in the advancement and protection of electronic devices.

How is Gorilla Glass Made?

Gorilla Glass is produced using advanced technologies like ultrafast laser systems, moth-eye nanopillar structures, micromachining, and hard aluminum-magnesium boride films for enhanced functionality, durability, and strength in various applications. These are the steps to make Gorilla Glass:

1. Fusion-draw Process

Gorilla Glass is produced using the fusion-draw process, which consists of several steps. Initially, molten glass is formed, and a fusion isopipe made of refractory ceramic is heated to a glass production temperature inside a furnace. The fusion isopipe is then subjected to stress-riser events to reduce stress levels, followed by a temperature-hold period to stabilize the temperature distribution in the furnace, further reducing stress levels. The glass ribbon forming process involves cooling the glass ribbon at different rates from the initial temperature to the exit temperature, with specific cooling rates for different segments of the process to ensure quality and integrity of the glass sheet. Additionally, a glass manufacturing system that utilizes a fusion draw process and a vertical roll apparatus is used to produce textured glass sheets of varying thicknesses.

2. Ion-Exchange Process

Gorilla Glass is produced using an ion-exchange method, as described in various scientific papers. This process entails replacing small alkali ions within the glass with larger alkali ions from a molten salt bath through inter-diffusion, creating a compressive stress profile near the glass surface that improves its strength and resistance to damage. This technique has been effectively utilized to chemically strengthen alkali-free glass by exchanging barium salts under high pressure and temperature, resulting in surface compressive stress values of approximately 200 MPa. Furthermore, the impact of potassium-to-sodium ion exchange on the nonlinear refractive index of Gorilla Glass has been investigated, demonstrating a higher nonlinear refraction value at the surface compared to the interior, with a penetration depth constant of around 50 μm. Another approach involves a non-immersion method, where a mixture of salt solution and metal oxide particles is applied to the glass surface to create a film, facilitating ion exchange between the membrane and alkali ions in the glass via liquid salt at elevated temperatures. This thorough ion-exchange process produces chemically strengthened glass products with high peak compressive stress, enabling them to withstand bending stresses and resist damage from impacts, making them suitable for applications such as flexible and foldable displays.

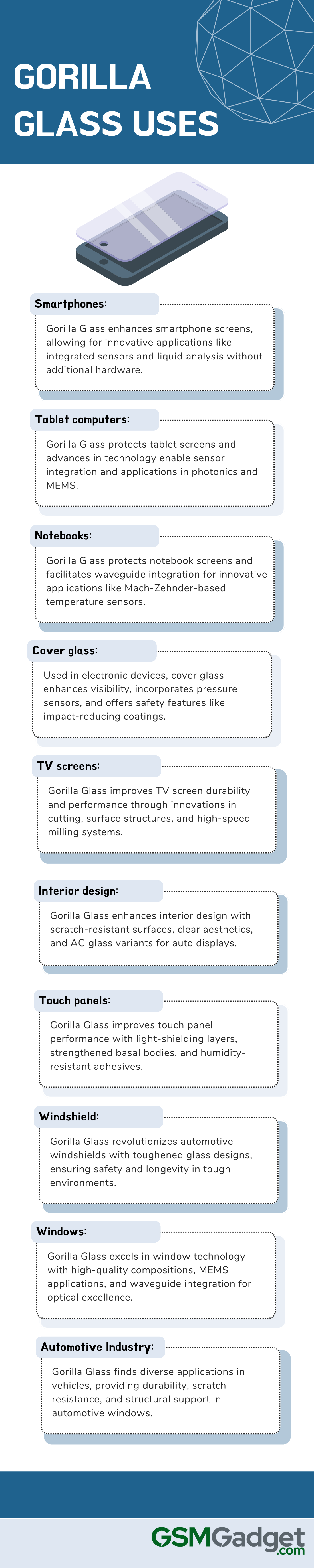

Gorilla Glass Uses

Gorilla Glass, with its high fracture toughness and hardness, is used in various fields like MEMS/NEMS, waveguide fabrication, micromachining, and organic thin-film transistor arrays due to its resistance to scratching. Some of the uses of Gorilla Glass are:

1. Smartphones

Gorilla Glass, an innovative material, is widely used in smartphones to protect their screens from damage. Researchers have explored novel applications of Gorilla Glass in smartphones, such as integrating sensors directly into the glass itself. This integration enables the development of near-surface waveguides that are sensitive to changes in refractive index, allowing for liquid analysis on the smartphone screen without the need for additional hardware. Studies have also focused on characterizing Gorilla Glass from different manufacturers and phone models, highlighting the unique thermoluminescence and photo transferred thermoluminescence signals specific to various glass generations, manufacturers, and models. Furthermore, investigations have shown significant variability in Electron Paramagnetic Resonance and Thermoluminescence signals among Gorilla Glass samples, suggesting potential differences in UV exposure during the manufacturing processes.

2. Tablet computers

According to the article, Gorilla Glass, known for its exceptional durability and scratch resistance, is widely used in tablet computers to provide strong protection for their screens. Originally developed for touchscreen electronics, Gorilla Glass has become a common feature in modern devices, protecting billions of smartphones, tablets, and laptops worldwide. Recent advancements have even incorporated sensors directly into Gorilla Glass, demonstrating its versatility beyond just protection, with applications such as analyzing liquids directly on smartphone screens without the need for additional accessories. Additionally, Gorilla Glass has attracted attention in the field of photonics due to its optical properties, making it a potential candidate for advanced optical devices. Studies are focusing on its nonlinear optical response and the fabrication of waveguides using femtosecond laser pulses. The material’s flexibility, high fracture toughness, and micromachining capabilities make it a promising substrate for MEMS applications, offering advantages such as the ability to bend without breaking.

3. Notebooks

Gorilla Glass, well-known for its durability and scratch-resistant properties, is widely used in applications beyond smartphones and tablets. In the field of notebooks, Gorilla Glass acts as a protective barrier, shielding screens from damage. Furthermore, advancements in Gorilla Glass technology have allowed for the integration of high-quality waveguides and photonic devices in notebooks, demonstrating the material’s versatility. Researchers have successfully shown the fabrication of waveguides with minimal loss in Gorilla Glass, opening up possibilities for innovative applications such as Mach-Zehnder-based temperature sensors. Additionally, the all-laser machining method for glass and brittle materials has improved the precision and quality of manufacturing processes for display panels in notebooks, ensuring chip and crack defect sizes of less than 10 μm in the edges. The evolution of Gorilla Glass continues to increase its usefulness in enhancing the durability and functionality of notebooks.

4. Cover glass

Cover glass, such as Gorilla Glass, serves various purposes in electronic devices. It can enhance visibility by incorporating features like anti-glare layers and anti-reflection films, ultimately improving image clarity. Additionally, cover glass can be optimized for scratch resistance and mechanical strength, making it suitable for applications like auto interior displays. Moreover, cover glass can be utilized as a top substrate for pressure sensors, enabling the sensing of pressure to trigger functions in image display modules. Furthermore, advancements in cover glass technology include the use of impact-reducing ink coatings to minimize scattering and reduce impact when the glass is broken, enhancing safety and durability. Another innovative application involves using cover glass for electrostatic touch screens, incorporating unique textures and metallic decorations to prevent malfunctions and add design characteristics.

5. TV screens

Gorilla Glass is used in a variety of applications in TV screens, demonstrating its versatility and durability. Research has shown that Gorilla Glass is utilized in TV screens for tasks such as display panel cut-outs, chamfering, and interior feature manufacturing, showcasing its ability to be machined with lasers with minimal defects in the edges. Studies have also investigated the creation of moth-eye nanopillar structures on Gorilla Glass surfaces, which improve transmission and enable features like self-cleaning, anti-fogging, and stain-resistance, all of which could be beneficial for TV screen applications. Furthermore, a high-speed milling system combined with a nanosecond pulsed laser has been developed to cut Gorilla Glass substrates for TV screens, resulting in improved cut quality and surface morphology. These advancements collectively enhance the performance and durability of Gorilla Glass in TV screens, making it a preferred choice for manufacturers.

6. Interior design

Gorilla Glass, known for its durability and scratch-resistant properties, has been widely used in interior design applications. Originally developed for touchscreen devices, Gorilla Glass has been adapted to meet the needs of interior design, providing both strength and aesthetic appeal. Its scratch-resistant and strong nature make it a suitable material for various interior design elements such as display panels, cut-outs, chamfers, and interior features, with minimal defects in the cut edges. The versatility of Gorilla Glass also extends to creating clear and transparent surfaces, allowing light to pass through and enhancing spatial aesthetics in interior spaces. Additionally, AG glass, a variant of Gorilla Glass, offers strong scratch resistance and mechanical strength, making it a suitable choice for interior applications such as auto displays, where optimizing surface treatment is essential for maintaining clarity and resolution.

7. Touch panels

Gorilla Glass is widely used in touch panels due to its durability and functionality enhancements. Various methods have been explored in touch panel technology to improve performance and reliability. For example, the use of a white light-shielding layer containing white metal oxide in OGS touch panels enhances functionality. Additionally, preparation methods for touch screens now include strengthening glass basal bodies, forming light shield layers, and conductive circuits, resulting in touch screens with enhanced strength and efficiency. Furthermore, innovations such as incorporating hygroscopic fine particles in the adhesive of glass touch panels contribute to exceptional high-temperature and high-humidity resistance, ensuring prolonged usability in diverse environments. These advancements collectively contribute to the widespread adoption of Gorilla Glass in touch panels, improving their performance and longevity in various electronic devices.

8. Windshield

Gorilla Glass, known for its durability and scratch resistance, has been widely used in various industries, including the automotive sector for windshields. The toughened glass windshields feature innovative designs such as slanting stitch-type wind holes, adjustable fan blade districts, and fixed fan blade districts to ensure even cooling and stress distribution during the toughening process. Originally developed for touchscreen devices, Gorilla Glass’s success is attributed to its chemical composition, which utilizes rigidity theory to enhance durability and scratch resistance. This advanced material has revolutionized the automotive industry by providing durable and long-lasting windshields that can withstand impacts and environmental elements, ensuring driver safety and extending the service life of the glass.

9. Windows

Gorilla Glass, renowned for its durability and transparency, is utilized in a variety of window technologies. Glasses composed of BaO-Ga2O3-GeO2, known as BGG glasses, have been successfully manufactured into high-quality windows with minimal wavefront error, making them well-suited for a range of window applications within the 0.5-5 μm wavelength range. Additionally, micromachining of Gorilla Glass has shown promise for MEMS applications due to its flexibility and high fracture toughness, with wet etching techniques producing precise microstructures without sharp edges. Moreover, Gorilla Glass has been employed in the creation of waveguides and photonic devices with exceptional performance, achieving a minimal loss of 0.18 dB/cm in waveguides, demonstrating its potential for advanced optical applications. These various uses highlight Gorilla Glass as a versatile and dependable material for window technology, offering both durability and optical excellence.

10. Automotive Industry

Gorilla Glass, known for its exceptional durability and scratch resistance, has found significant applications in the automotive industry. AG glass, a variant of Gorilla Glass, has demonstrated robust scratch resistance and mechanical strength comparable to Gorilla Glass without AG. This material innovation aligns with the automotive industry’s focus on enhancing comfort and security levels through the development and application of new materials and technologies. Moreover, the use of Gorilla Glass in vehicle glass devices showcases its versatility, as it can be integrated to reduce noise from electrical heating wires in a simple configuration. The incorporation of Gorilla Glass in automotive windows not only ensures durability but also provides support through embedded support members and retainers, enhancing the overall structural integrity of the glass window.

Composition and Properties of Gorilla Glass

Gorilla Glass is well-known for its exceptional chemical durability and strength, which are attributed to its specific compositions and properties. Various glass compositions have been studied for their durability, including those containing SiO2, B2O3, Na2O, and ZnO. Additionally, the chemical temper ability and alkali resistance of glasses have been linked to phases such as albite, silicon dioxide, and other constituents. The bonding composition of glass materials, including polyhydroxy polymers, contributes to strong adhesion and impact resistance in laminated glass products. Furthermore, the presence of Fe2O3 in glass compositions has been shown to enhance chemical durability, resulting in transparent glasses with low dissolution rates. These factors collectively contribute to Gorilla Glass’s scratch resistance, impact resistance, and overall durability, making it a preferred choice for various applications that require robust glass materials.

Advantages of Gorilla Glass

Corning’s Gorilla Glass is a durable, flexible, and fracture-resistant material ideal for various applications, including smartphones, tablets, MEMS, photonic devices, and microstructure development due to its unique composition. The advantages of Gorilla Glass are:

1. Strong, Durable, and Rigid

Gorilla Glass, renowned for its strength and durability, offers a variety of benefits. Originally created for touchscreen devices, it has expanded to be used in diverse applications due to its robust characteristics. According to the article, the material’s outstanding scratch resistance and toughness make it well-suited for safeguarding smartphones and tablets from damage. Furthermore, Gorilla Glass demonstrates flexibility and high fracture toughness, making it appropriate for microstructures in MEMS applications. The glass’s composition, developed using rigidity theory, ensures it can endure significant bending and stress without fracturing. Additionally, examinations of Gorilla Glass samples have shown variability in Electron Paramagnetic Resonance and Thermoluminescence signals, indicating its unique properties and potential for further exploration in various technological fields. In conclusion, Gorilla Glass is distinguished for its strength, durability, and rigidity, making it a versatile and dependable material for a wide range of applications.

2. Improved Scratch-Resistant

Gorilla Glass offers significant advantages due to its improved scratch resistance. The development of scratch-resistant anti-reflective (SRAR) coatings on Gorilla Glass substrates enhances its durability and longevity. Glass-based articles with stress profiles designed for improved scratch resistance demonstrate the effectiveness of specific compositions and stress levels in enhancing scratch resistance properties. Furthermore, the fabrication of hard aluminum-magnesium boride (BAM) films on Gorilla Glass significantly increases its scratch resistance, as evidenced by the Vickers hardness and Young’s modulus of the coatings. Gorilla Glass’s scratch resistance is further enhanced by its chemical composition, where the replacement of some sodium ions with potassium ions contributes to its hardness and scratch-proof qualities. Overall, Gorilla Glass stands out for its exceptional scratch resistance, making it a preferred choice for various applications requiring durable and long-lasting glass materials.

3. Impact-Resistant

Gorilla Glass provides exceptional impact resistance due to its unique composition and design. The glass is engineered with high surface compressive stress, a large stress layer depth, and excellent mechanical properties, giving it a high level of impact resistance. Additionally, the impact-resistant glass lens, which consists of an outer glass lens, inner glass lens, and support strips with a vibration damper plate, offers effective cushioning and protection upon impact, preventing breakage and ensuring user safety. Furthermore, the impact-resistant glass plate, which includes hard alloy blocks in a circular ring structure, provides structural stability and impact resistance, making it suitable for applications requiring durability and safety, such as in concrete pump cutting rings. Overall, Gorilla Glass is known for its ability to effectively withstand impacts, making it a preferred choice for various industries and applications.

4. Thin and Lightweight

Gorilla Glass offers significant advantages in terms of thinness and lightweight properties. Its chemically strengthened ultrathin composition allows for reduced thickness while maintaining high strength, surpassing conventional glass limitations. The unique manufacturing process of Gorilla Glass ensures precise thickness control and pristine surfaces, enhancing the overall quality of the glass. This material has been successfully utilized in various applications, including consumer electronics and automotive windshields, showcasing its durability and lightweight characteristics. Additionally, Gorilla Glass has been explored for novel uses such as in waveguides and photonic devices, demonstrating its versatility and adaptability to different industries. The material’s high fracture toughness and flexibility make it ideal for microstructures in MEMS applications, further highlighting its advantages in lightweight and durable designs.

5. Enhanced Touch Sensitivity

Gorilla Glass, renowned for its durability and scratch resistance, offers improved touch sensitivity as a result of its innovative design. Through the incorporation of specific chemical compositions and the application of rigidity theory, Gorilla Glass achieves a balance between flexibility and rigidity, resulting in a material that is not only long-lasting but also highly responsive to touch inputs. Additionally, touch-sensitive screens made with strengthened glass benefit from features such as sound wave transmitting transducers and ultrasonic wave receiving transducers, which enable efficient conversion of acoustical signals to electrical signals for seamless touch interactions. Moreover, the integration of conductive coils, capacitors, and inductance-to-digital converters in touch-sensitive glass barriers enhances touch sensitivity by accurately detecting touch points on the screen. In conclusion, Gorilla Glass stands out for its ability to provide both durability and improved touch sensitivity in various touch-sensitive devices.

6. Versatile and Flexible

Gorilla Glass offers numerous advantages, making it a versatile and flexible material for various applications. Firstly, Gorilla Glass demonstrates exceptional durability and scratch resistance, making it ideal for use in smart devices such as smartphones and tablets. Additionally, the material’s unique properties enable the fabrication of high-quality photonic devices and waveguides with minimal loss, highlighting its adaptability for advanced technologies like temperature sensors and authentication security systems. Furthermore, Gorilla Glass displays flexibility and high fracture toughness, allowing for the creation of microstructures like microcantilevers that can bend significantly without breaking, a significant departure from traditional brittle glasses like Pyrex or Borosilicate. This combination of strength, flexibility, and optical quality makes Gorilla Glass a versatile and flexible material suitable for a wide range of innovative applications.

7. Optical Clarity

Gorilla Glass offers exceptional advantages in optical clarity due to its unique properties and applications. The glass, known for its durability and scratch-resistance in smart devices, also provides unparalleled transparency crucial for optical applications like waveguides. Its composition, designed with rigidity theory, ensures high clarity and scratch-resistance. Gorilla Glass’s optical clarity is vital for various devices, enabling the exploration of microscopic and macroscopic worlds through lenses, microscopes, and telescopes. Moreover, the glass’s ability to host high-quality waveguides with minimal loss values further highlights its suitability for optical applications requiring superior transparency. Overall, Gorilla Glass stands out for its optical clarity, making it a preferred choice for a wide range of optical devices and systems.

8. Compatibility with Protective Coatings

Gorilla Glass offers several advantages, particularly in its compatibility with protective coatings. Coating compositions designed for protecting display glasses, such as Gorilla Glass, are non-reactive to touch components and metal electrodes, allowing for over-coating without compromising functionality. Additionally, applying protective films, such as PET films, electrostatically on coated glass surfaces enhances adsorptive performance and ensures firm adhesion, providing a simple yet highly effective protective layer. Furthermore, depositing hard aluminum-magnesium boride (BAM) films on Gorilla Glass significantly increases its hardness and Young’s modulus, improving resistance to cracking and enhancing durability. By incorporating protective layers with specific characteristics, such as high optical transmittance and hardness, Gorilla Glass maintains its strength while benefiting from additional protective features for various applications.

9. Heat-resistant

Gorilla Glass is well-known for its heat-resistant properties, which offer various advantages due to its unique composition. Different formulations of heat-resistant glass use a variety of raw materials to improve durability and thermal stability. For example, compositions that include elements such as silicon dioxide, borosilicate, and glass fibers have increased hardness and resistance to high temperatures, preventing cracking or breakage when exposed to heat. In addition, the addition of components like zinc oxide, ytterbium oxide, and tantalum oxide results in low thermal expansion coefficients, high strength, and rigidity, ensuring the glass remains resilient under different thermal conditions. Furthermore, innovative designs such as patterned layers further enhance the functionality of heat-resistant glass, allowing for intricate patterns to be created while maintaining strong heat resistance, making it suitable for applications like cooker top plates.

Drawbacks of Gorilla Glass

Gorilla Glass, despite its durability and scratch resistance, faces challenges in photonic structures, high thermal expansion, and fragility, impacting industries like aerospace and shipping. Some of the drawbacks of Gorilla Glass are:

1. Price

According to the article, the disadvantages of Gorilla Glass include its high cost, which can significantly impact its widespread adoption. Despite its exceptional durability and scratch resistance, the production cost of Gorilla Glass may restrict its availability to a larger market. The development of Gorilla Glass required precise chemical design to achieve its unique properties, such as enhanced scratch resistance and durability. This meticulous composition, based on rigidity theory, enhances its effectiveness but also increases production costs, ultimately affecting its market price. Although Gorilla Glass has transformed the durability of glass products, its premium price may hinder its incorporation into different industries and consumer goods.

2. Little-to-No Repair Options

Gorilla Glass, known for its durability and scratch resistance, presents challenges in terms of repair options due to its unique composition. The rigidity theory applied in the design of Gorilla Glass highlights the importance of specific chemical compositions for its strength and resilience, making repair difficult. Furthermore, research has shown that Gorilla Glass sourced from different suppliers and screens display significant variability in Electron Paramagnetic Resonance (EPR) and Thermoluminescence (TL) signals, suggesting potential differences in material properties that could complicate repair processes. These factors contribute to the limited repair options for Gorilla Glass, as its specialized design and variability among samples create obstacles in achieving seamless repairs. According to the article, this results in a situation where few to no repair options are available for this innovative yet complex material.

3. Environmental Impact

The environmental impact of Gorilla Glass, despite its durability and anti-glare properties, has drawbacks. The production process of toughened glass involves the use of specific chemicals and materials, such as ammonium fluoride and polyatomic alcohol, which can have environmental implications due to their composition and manufacturing requirements. Additionally, the disposal of waste glass, a key component in foam glass production, poses challenges in sustainable waste management, leading to increased waste proportions and strain on landfill capacities. While foam glass made from waste glass can be beneficial in terms of resource conservation and energy efficiency, the production stages, particularly foaming and annealing, contribute significantly to environmental impacts such as global warming potential and acidification potential

. Therefore, despite its technological advancements, the environmental footprint of Gorilla Glass remains a concern that necessitates further research and sustainable practices.

4. Not 100% Shatterproof

Gorilla Glass, known for its durability and scratch resistance, is not completely shatterproof due to its inherent characteristics. While Gorilla Glass has made significant advancements in the industry with its strength, it still has limitations. The micromachining of Gorilla Glass for MEMS applications has shown its flexibility and high fracture toughness, but it can still shatter, as seen with microcantilevers bending without breaking. Additionally, the high thermal expansion coefficient of Gorilla Glass presents challenges for anodic bonding processes, despite its antibacterial resistance and other beneficial properties for MEMS/NEMS applications. Therefore, while Gorilla Glass offers exceptional strength and resilience, it is not entirely shatterproof, underscoring the importance of recognizing its limitations in different technological applications.